OUR PRODUCTS

CONTACT US

Factory Address:No. 18 Xianshan Road, Chengyang District,Qingdao City, Shandong Province

Department of International

Domestic Market 1:0086-13730937861

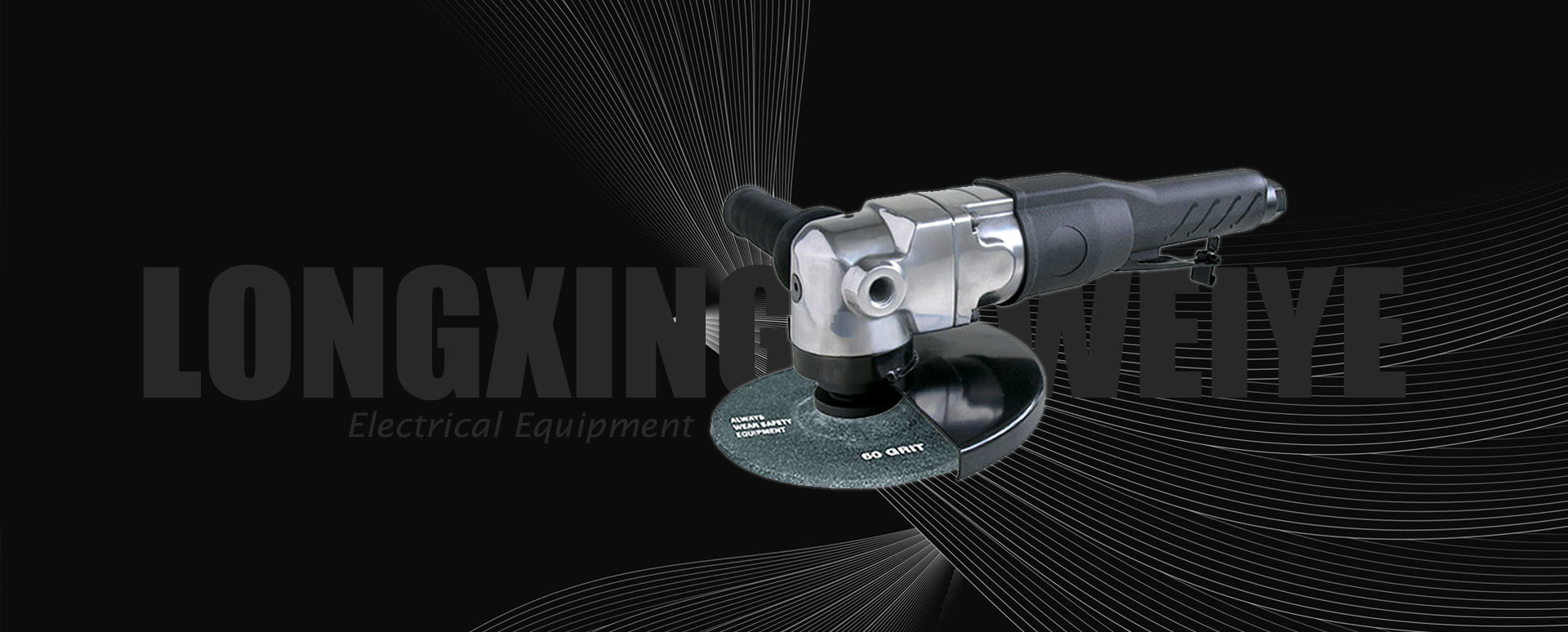

Reciprocating ultrasonic grinding machine 0.7MM

Classification:

Mould Polishing Tools

Keyword:

Product description

Reciprocating ultrasonic grinding machine 0.7MM

Lightweight pen-like structural design, with small volume, high speed, low noise, high torque, low air consumption, light weight and stable (very low jitter), easy to operate, fast and convenient, widely used in various Mould (shoe mold, tire mold, pen mold, all kinds of high and low voltage electrical appliances, household appliances molds, plastic shell switch molds, etc.), hardware products (faucets, zippers, hardware tools and all kinds of complete sets of equipment, etc.), and glass, Stone, crafts, jewelry, circuit board manufacturing, etc. All industries that require rough trimming, cutting, grinding, engraving, trimming, and mirror polishing operations.

Product features and applications:

The linear reciprocating and circumferential oscillating pneumatic ultrasonic grinding machine adopts the Japanese pneumatic turbine engine structure technology, and has the advantages of small volume, good hand feeling, low vibration, low noise, high speed and large torque. It can use different fixtures for grinding operations, and can hold industrial oil stone, ceramic fiber whetstone, trowel, or bamboo chip, etc., in the groove of the mold or hardware, wall, rib, R angle, fine Sewing and other places that are difficult to machine by hand, for quick grinding work, so that the surface finishing, roughing and mirror polishing of the tooling surface can be completed at one time, so that the surface roughness of the tooling can be quickly reduced until the mirror surface is reached. Instead of the effect, you can do more with less:

1. High-torque pneumatic turbine engine structure precision device for excellent work efficiency

2. Multi-purpose high-tech tip tool

3. No heat, high efficiency drive

4. Control the grinding speed by air conditioning

5. Differentiating the grinding stroke in different colors

6. Ergonomic handle design makes the operation more comfortable

Scope of application:

1. Mold polishing, mirror processing.

2. The die casting removes the flash and removes the burrs.

Complete a variety of tasks quickly.

|

|

||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

|||||||||

|

|||||||||

Previous Page

Position:

Position: